NO.1188 LANZHOU WEST R.D JIAOZHOU QINGDAO CHINA

1. Improve product quality and reduce defective rateThe plastic dryer effectively removes moisture from raw materials by accurately controlling temperature and humidity. Plastic particles that have not been dried will produce bubbles, silver streaks and other defects during the injection molding process, which will seriously affect the appearance and mechanical properties of the product. The use of professional plastic drying equipment can significantly reduce the product defect rate, improve the quality consistency of the finished product, and win more customer trust for your business.

2. Improve production efficiency and shorten the production cycleThe plastic dryer adopts a high-efficiency hot air circulation system, which has a fast drying speed and can greatly shorten the pretreatment time of raw materials. Compared with the traditional natural drying or simple drying method, the automatic drying equipment can realize continuous feeding, ensure the stable operation of the production line, avoid production interruption caused by insufficient preparation of raw materials, and increase the overall production efficiency by more than 30%.

3. Reduce energy consumption costs and save enterprise expensesQingdao Zhongbangling's plastic dryer adopts advanced energy-saving technology, with high thermal efficiency and low energy consumption. Compared with the traditional drying method, the equipment is equipped with an intelligent temperature control system, which can automatically adjust the drying parameters according to the characteristics of different raw materials, avoid energy waste, and save considerable operating costs for enterprises for long-term use.

4, prolong the life of the mold, reduce the maintenance cost of the wet plastic raw materials in the injection molding process will produce hydrolysis reaction, release corrosive substances, accelerate the aging and damage of the mold. The use of plastic dryers to ensure that the raw materials are fully dry can effectively reduce mold corrosion, extend the service life of molds by 30%-50%, significantly reduce the frequency of mold maintenance and replacement, and save a lot of equipment maintenance costs for enterprises.

5. Adapt to a variety of raw materials and improve production flexibilityModern plastic dryers can process a variety of engineering plastics such as PC, ABS, AS, nylon, etc., and one equipment can meet a variety of production needs. Especially for hygroscopic raw materials such as PET, PBT, etc., professional drying equipment is indispensable. This versatility allows businesses to respond flexibly to different order needs and improve market resilience.

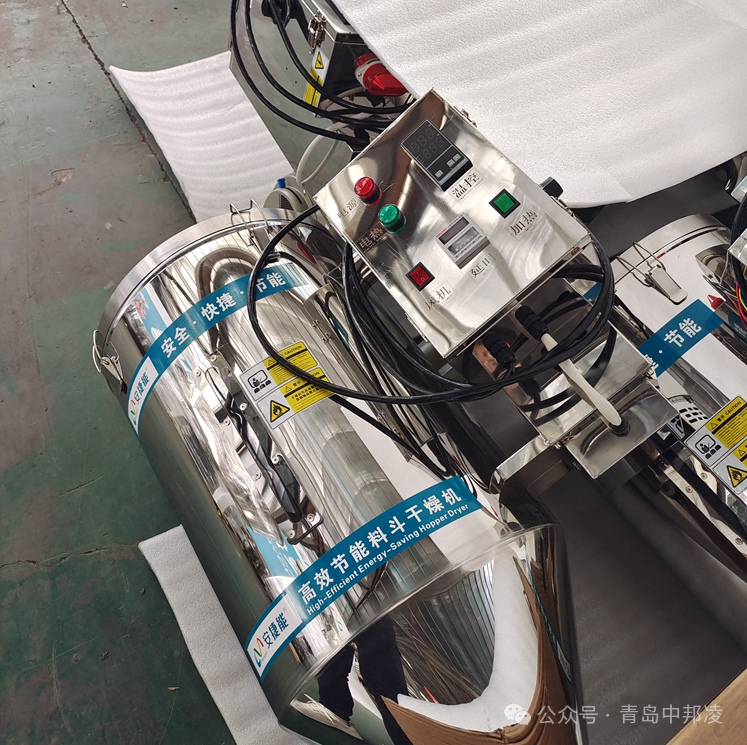

As a professional supplier of plastic auxiliary equipment, Qingdao Zhongbangling provides dryer series with different capacities from 6kg to 500kg to meet the needs of various injection molding enterprises. Our equipment is made of high-quality stainless steel liner and equipped with branded thermostats to ensure stable and reliable drying results.

In the increasingly competitive injection molding industry, investing in a high-quality plastic dryer is not only a necessary choice to improve product quality, but also a wise decision for enterprises to reduce costs and increase efficiency. Welcome to contact Qingdao Zhongbangling, we will provide you with professional drying solutions and high-quality after-sales service to help your injection molding business to the next level!